Most Popular Products

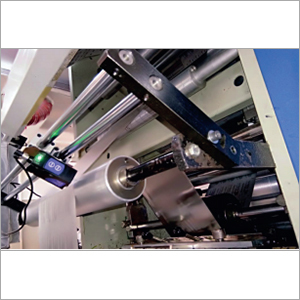

Inspection SystemKnown for its computer controlled operation or automatic functioning, our range of Inspection System is used for trouble free checking of various industrial procedures in order to confirm their industry specified standards. Equipped with intelligent sensor, this industrial equipment easily integrate with advanced sensor based technology to maintain its accuracy. Automatic detection mechanism of this system not only saves installation duration of various machinery, but also reduces operation hour by eliminating operator based monitoring process. Moreover, its latest detection procedure does not stop production or hamper productivity. Besides preventing wastage, our array of Inspection System safeguards equipments against all sorts of external damages. Sturdy construction, user friendly design, affordable price, energy efficient operation and less maintenance cost are its main characteristics. Features: 1) Offered system ensures higher profit at less investment. 2) Powered by electricity, this system consumes less energy. 3) Fast and accurate operation. 4) Less installation duration.

|

|

|

|

PRECISION CUTTING SYSTEMS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese