Showroom

Barcode Stickers & Equipment are robust and unique symbols, which can be read and verified on each carton based on the product name, company name, manufacturing location and other such factors. The user interface of barcode reader is simple and operator friendly.

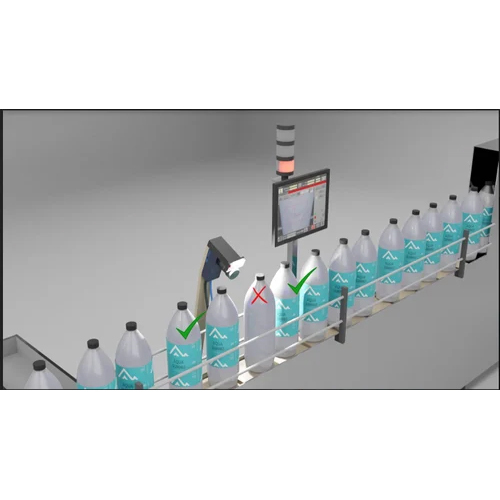

Vision inspection systems have applications in a wide

range of industries, including the automotive, electronics, pharmaceutical,

food, and beverage industries.

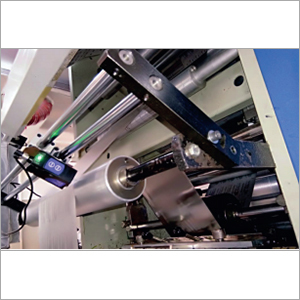

Our cutting-edge label numbering inspection system is

built with 100% verification technology of printed texts and images at a faster

rate. The machine can be highly meaningful and durable.

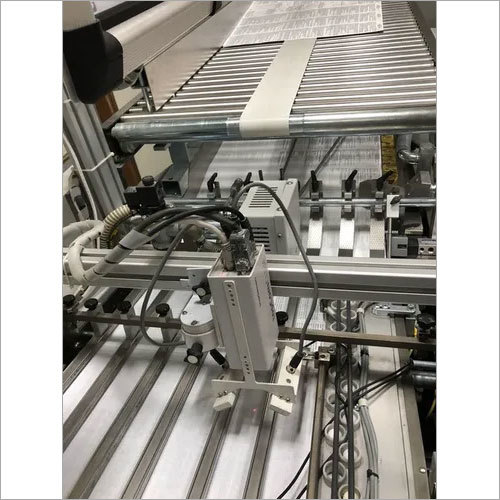

A detector & sensor can be mounted in machines where sheet materials, preferable paper is used. Based on the ultrasonic technology, it can detect double layers, single layer and no sheet material.

|

PRECISION CUTTING SYSTEMS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |